In interior design, DIY projects, and industrial painting, a suitable Paint Brush is often key to the quality of the final product. With the diversification of market demands, standard brushes are no longer sufficient to meet the requirements of special paints or high-precision applications. Therefore, custom Paint Brush have become the preferred choice for many professional paint suppliers, brand retailers, and DIY enthusiasts.

Content

Why Choose Custom Paint Brush?

The market offers a wide variety of ready-made brushes, but the advantage of customization lies in precise matching.

Performance Optimization: Customize the bristle material according to the viscosity of the paint (e.g., water-based, oil-based, or varnish).

Brand Enhancement: Engraving your company logo on the brush handle enhances brand professionalism and market recognition.

Ergonomic Design: Customize the handle shape and weight to reduce hand fatigue during long periods of application.

Core Elements of Custom Paint Brush

Before starting the customization process, understanding the following key components will help you make the best decision:

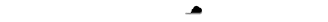

1. Bristle Types

The bristles are the soul of a paintbrush. Common choices include:

Natural boar bristles: Best suited for oil-based paints, dyes, and varnishes, offering high paint absorption and even application.

Synthetic fibers (nylon/polyester): Suitable for water-based latex paints, offering excellent shape retention and abrasion resistance.

Mixed bristles: A balance between durability and paint absorption.

2. Brush Head Shape and Size

Different brush shapes are suitable for different tasks:

Flat brush: Suitable for even application on large, flat surfaces.

Angled brush: Designed for window and door frames, corners, and fine edge sealing.

Round brush: Commonly used for decorative painting or narrow areas.

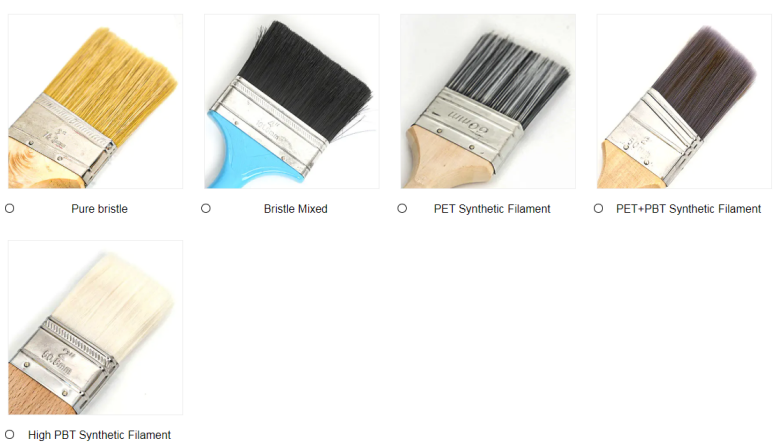

3. Handle Material and Appearance

The handle not only determines the grip but is also an important space for brand display. You can choose from:

Solid wood handles (beech, birch): Classic feel, sweat-absorbent and non-slip.

Plastic or composite materials: Lightweight and durable, with a wide range of colors.

Custom Logo: Laser engraving, screen printing, or hot stamping are supported.

4. Ferrule

The metal ring connecting the bristles to the handle. High-quality Paint Brush are typically made of stainless steel or tin-plated iron and cured with strong epoxy resin to ensure no bristle shedding during application.

How to Start Your Customization Journey?

The customization process is actually very simple. At Pro-Charger, we offer one-stop OEM/ODM services:

Requirements Communication: Define your intended use (e.g., professional architecture, art painting, or home DIY).

Specifications Confirmation: Choose bristle length, thickness, handle color, and packaging method.

Sample Production: We will produce samples according to your requirements for your testing.

Mass Production: After sample confirmation, a strict quality control production process ensures that every paintbrush meets export standards.

Choosing the right paintbrush not only improves work efficiency but also extends the life of your coating. Through customization services, you can obtain products that best meet market demands.

If you have needs for bulk purchasing or brand customization, please contact us immediately. Our professional team will provide you with detailed quotations and technical support. Choosing a reliable Paint Brush customization partner is the first step toward building a strong brand.

Español

Español